-

The Future Of Online And Mobile Banking

July 25, 2016 -

Schools to Hold Programming Courses In 2016

July 25, 2016 -

Hello world!

January 8, 2022

Categories

- Membership (2)

- Uncategorized (1)

Archive

- January 2022 (1)

- July 2016 (2)

Applications

Power

Power sector is among the most critical components of infrastructure, crucial for the economic

growth and welfare of nations. Power sector is one of the most diversified. Sources of power

generation range from conventional sources such as coal, lignite, natural gas, oil, hydro and nuclear

power to viable non-conventional sources such as wind, solar, and agricultural and domestic waste.

Oil And Gas

We offer heat exchangers for critical applications for oil & gas projects. It also provides its customers in the oil and gas industry with a broad range of shell & tube heat exchanger, Air Cooled Heat Exchangers. This sector provides crude oil, natural gas, and value-added products to major oil and gas refining companies.

In addition to traditional products, Positron also focuses majorly on a 20 years tradition of innovation and new product development. It has supplied heat exchangers successfully in various oil & gas plants and given the desired performance; operating temperatures and pressures and site locations and is extremely reliable.

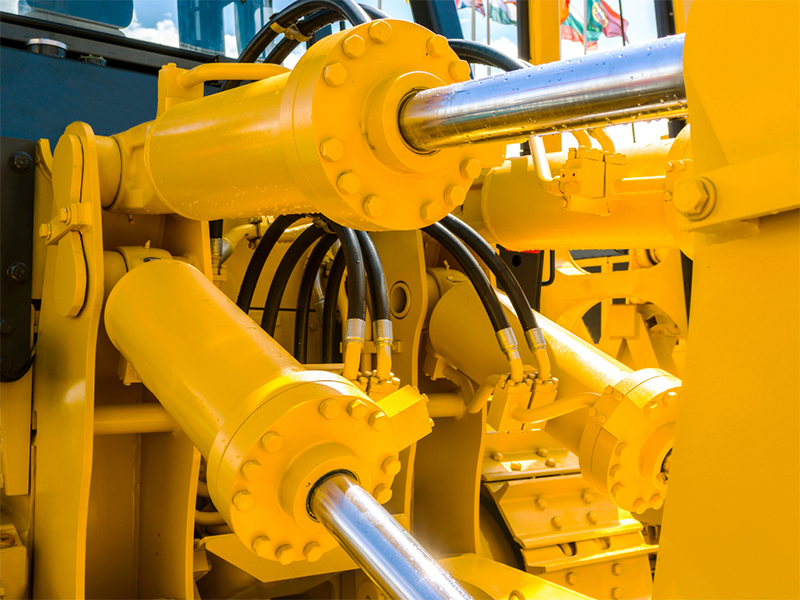

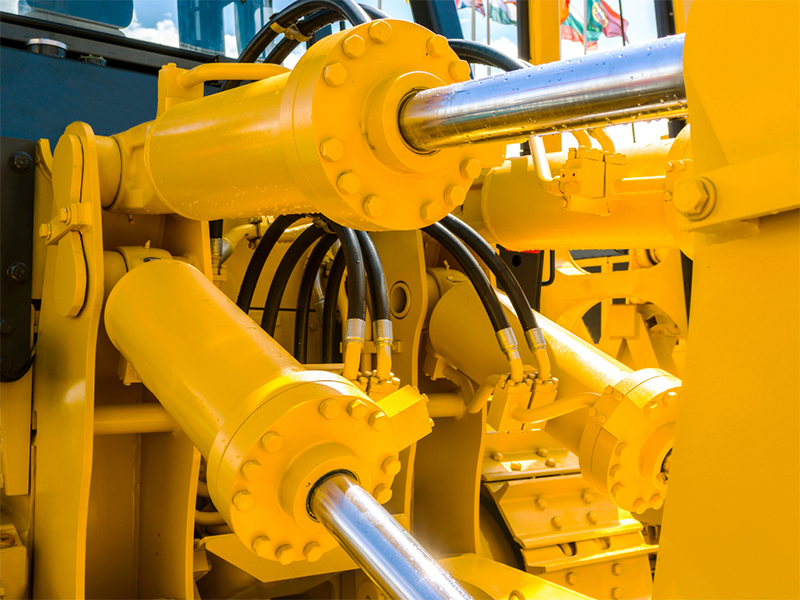

Hydraulics & Lubrication

Positron being situated in Belgaum, India’s one of the old hydraulic hubs, has provided heat exchangers to equipment like hydraulic power pack, hydraulic press, & lubrication oil systems. It gets prioritized opportunities in developments & providing solutions for well defined projects in hydraulics & Lubrication.

Marine Engineering

Marine engineering is the discipline of applying engineering sciences to the development, design, operation and maintenance of watercraft propulsion and on-board systems and oceanographic technology. The chemical environment faced by heat exchangers is far harsher than nearly anywhere on land. Marine engineers are concerned with surface protection and preventing galvanic corrosion in every project.

We have provided heat exchangers to different projects of marine engineering, by using the corrosion resistant materials, supplied by reliable manufacturers for on-board, on-shore & off- shore applications.

Steel

Steel industries are among the most important industries, and they include the major processes of heat treatment during the production of steel & also gen-sets for power generation. Hence there is a need to manage & stabilize the temperatures at various stages of manufacturing.

We have supplied heat exchangers to various processes in steel plants.

Sugar

The sugar industry subsumes the production, processing and marketing of sugars . Globally, most sugar is extracted from sugar cane and sugar beet. The process includes the requirement of heating & cooling of slurry during the stages of production & also includes gen-sets for the power generation. These create a need for heat exchangers at various stages of production to stabilize & maintain the temperatures (Cooling & Preheating) of feed oil, water, sugar slurry and coal/biogas. We have supplied heat exchangers for various processes of heating, cooling & heat recoveries in the sugar industries.

HVAC Industries

Heating, ventilation, and air conditioning (HVAC) is the technology of indoor environmental comfort. Its goal is to provide thermal comfort and acceptable indoor air quality.

HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels and senior living facilities, medium to large industrial and office buildings such as skyscrapers and hospitals, vehicles such as cars, trains, airplanes, ships and submarines, and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fresh air from outdoors.

We have provided various heat exchangers in HVAC applications.

Pulp And Paper

Pulp & paper industries benefit more than others from specific industrial products or machines. Without heat exchangers, paper mills would have exceedingly high energy costs, which is bad for the environment as well as the purse size of the paper companies. Heat recovery is one of the important applications of heat exchangers in this industry as the runaway heat is used to recover water from the moist air, which can be utilized for the purpose of processing. Thus providing economical benefits.

Sewage Water treatment.

Sewage treatment is the process of removing contaminants from municipal wastewater, containing mainly household sewage plus industrial wastewater. The sludge accumulated in the wastewater treatment process must be treated and disposed of in a safe and effective manner. Heat exchangers are used in the process of heating & cooling of sludge during its treatment, such as heat recovery from sludge raising up sludge temperature before the treatment. We have provided heat exchangers for heating & cooling of sludge in wastewater treatment plants.

Power

Power sector is among the most critical components of infrastructure, crucial for the economic growth and welfare of nations. Power sector is one of the most diversified. Sources of power generation range from conventional sources such as coal, lignite, natural gas, oil, hydro and nuclear power to viable non-conventional sources such as wind, solar, and agricultural and domestic waste.

Oil And Gas

We offer heat exchangers for critical applications for oil & gas projects. It also provides its customers in the oil and gas industry with a broad range of shell & tube heat exchanger, Air Cooled Heat Exchangers. This sector provides crude oil, natural gas, and value-added products to major oil and gas refining companies. In addition to traditional products, Positron also focuses majorly on a 20 years tradition of innovation and new product development. It has supplied heat exchangers successfully in various oil & gas plants and given the desired performance; operating temperatures and pressures and site locations and is extremely reliable.

Hydraulics & Lubrication

Positron being situated in Belgaum, India’s one of the old hydraulic hubs, has provided heat exchangers to equipment like hydraulic power pack, hydraulic press, & lubrication oil systems. It gets prioritized opportunities in developments & providing solutions for well defined projects in hydraulics & Lubrication.

Marine Engineering

Marine engineering is the discipline of applying engineering sciences to the development, design, operation and maintenance of watercraft propulsion and on-board systems and oceanographic technology. The chemical environment faced by heat exchangers is far harsher than nearly anywhere on land. Marine engineers are concerned with surface protection and preventing galvanic corrosion in every project. We have provided heat exchangers to different projects of marine engineering, by using the corrosion resistant materials, supplied by reliable manufacturers for on-board, on-shore & off- shore applications..

Steel

Steel industries are among the most important industries, and they include the major processes of heat treatment during the production of steel & also gen-sets for power generation. Hence there is a need to manage & stabilize the temperatures at various stages of manufacturing. We have supplied heat exchangers to various processes in steel plants.

Sugar

The sugar industry subsumes the production, processing and marketing of sugars . Globally, most sugar is extracted from sugar cane and sugar beet. The process includes the requirement of heating & cooling of slurry during the stages of production & also includes gen-sets for the power generation. These create a need for heat exchangers at various stages of production to stabilize & maintain the temperatures (Cooling & Preheating) of feed oil, water, sugar slurry and coal/biogas. We have supplied heat exchangers for various processes of heating, cooling & heat recoveries in the sugar industries.

HVAC Industries

Heating, ventilation, and air conditioning (HVAC) is the technology of indoor environmental comfort. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels and senior living facilities, medium to large industrial and office buildings such as skyscrapers and hospitals, vehicles such as cars, trains, airplanes, ships and submarines, and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fresh air from outdoors. We have provided various heat exchangers in HVAC applications.

Pulp And Paper

Pulp & paper industries benefit more than others from specific industrial products or machines. Without heat exchangers, paper mills would have exceedingly high energy costs, which is bad for the environment as well as the purse size of the paper companies. Heat recovery is one of the important applications of heat exchangers in this industry as the runaway heat is used to recover water from the moist air, which can be utilized for the purpose of processing. Thus providing economical benefits.

Sewage Water treatment.

Sewage treatment is the process of removing contaminants from municipal wastewater, containing mainly household sewage plus industrial wastewater. The sludge accumulated in the wastewater treatment process must be treated and disposed of in a safe and effective manner. Heat exchangers are used in the process of heating & cooling of sludge during its treatment, such as heat recovery from sludge raising up sludge temperature before the treatment. We have provided heat exchangers for heating & cooling of sludge in wastewater treatment plants.

Recent Comments